Overview

Armor Polycarbonate

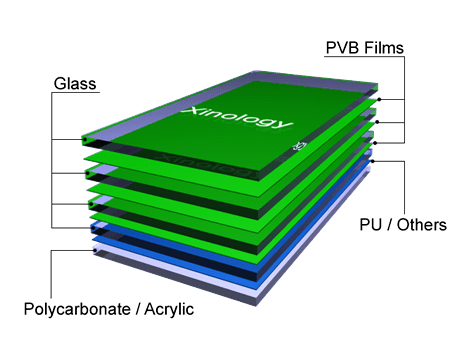

Glass Configurations Vary according to Designs & Applications

A sheet of armour glass is generally made out of all glass. However, there is a disadvantage. When it stops bullet, the outer layer of glass would be pierce by the bullet. The inner layer of glass absorbs the energy. However, the final layer would be splinter into chips. This flying glass chips travel in tremendous velocity and thus, stores enormous energy. They will create serious injuries and property damage despite tiny sizes and light in weight. This, sometimes known as secondary injuries, is also happen in other kinds of armor glass such as hurricane proof glass and explosive proof glass, etc.

A sheet of organic glass is chosen to prevent it from splinter. This organic glass is always used as the final layer. Polycarbonate is extensively used among different types of organic glass due to its strong impact strength and high transparency. A qualified polycarbonate could be more than 10 times tougher than tempered glass.

Polycarbonate could be used as first layer or inner layer of a sheet of armour glass for different applications. Polycarbonate is not as scratch proof as glass. When armour glass is applied in those areas where there are chances to get in direct contact with objects, polycarbonate is not recommended to use as first layer. For example, armour glass for vehicle is generally design not to use polycarbonate as outer layer due to dust in streets. When vehicle travels in high speed, still dust also travels in high velocity relatively when it gets hit on windshield. Thus, it scratches the polycarbonate. The windshield will become blur in long run.

Front Glass Layers absorb Bullet Energy

while Polycarbonate Prevents from

Shattering & Stops Bullet from Penetrating

When weight is one of the major concerns, polycarbonate is also selected to reduce the weight while not sacrificing impact strength. When polycarbonate is used, special formulated polyurethane is usually selected, instead of PVB, to be the plastic film interlay between glass and polycarbonate. Polycarbonate is often known as Lexan, Tuffak or Cyrolon which are brand names of different manufacturers.