POLISH-T-070

Feature

- Low Noise Generated Powerful Multi-Function Glass Polishing & Grinding Tool

- Light & Compact for Carry Around

- Heavy Duty Motor Spindle

- Processes Straight or Shape Glass Edge with Peripheral Wheels for Various Profile Edgings such as Pencil, Bull Nose & Flat with Arris

- Processes Both Exterior & Interior Glass Edges

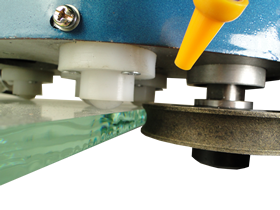

- Built in Water Cooling Pipe

- Very Suitable for Versatile Glass Processing Especially On Site Jobs

- Processing Speed at 1~3m/min.

- High Rotational Speed at 8000 RPM

- Low Power Consumption at 680W

- 220V/Single Phase

- Light Weight 5kg

- Compact Size 28 x 15 x 24cm

Operation

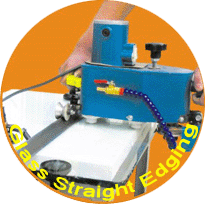

Straight Edging

Install suitable wheel on the tool. Put and fix guide track on glass. Adjust guide wheel of the tool until it is properly get in contact and freely moves along guide track. Make sure the tool lies properly flat on glass surface. Adjust wheel level until it is level with glass edge. Lock the wheel. Adjust feeding handle until wheel gets in contact with glass edge with adequate amount of glass grinding/eating. Turn on water coolant and adjust water hose until water flows on where wheel meets glass edge. Switch on the tool. When wheel spins constantly at high speed, move the tool with wheel against glass edge along guide track. Glass is started get grinded. Move the tool to and fro along straight glass edge. Experienced operator can handle the tool without guide track. When profile edge is done, replace with polishing wheel. No guide track is required when polishing. Bring polishing wheel along glass profile edge to and fro with pressure until adequate edge finish is obtained.

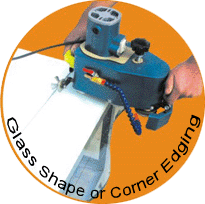

Shape Edging

No guide track is required. Move the tools along edge of shape glass. If it is round glass, locate circle center. Move the tool along glass edge with reference to the center. All other operation procedure shall be similar to straight edging.

Trouble Shooting

Do not standstill the tool during edging. If the tool is hold at an edging point for a while, edging point becomes concave. To fix it, adjust the tool so that grinding wheel “eats” more glass until concave point is recovered.

Grinding & Polishing Wheels

Standard Profile Edging Wheels Are Available For Pencil Edge & Flat/Arris. Other Profiles Wheels Are Provided On Request.

| Grinding Wheels | |||

| Profiles | Specifications | Glass Thickness | Model Numbers |

| Pencil Edge | Wheel Dia.Ф100mm | 4 mm | DWM-PE-100-22-4 |

| 5 mm | DWM-PE-100-22-5 | ||

| 6 mm | DWM-PE-100-22-6 | ||

| 8 mm | DWM-PE-100-22-8 | ||

| 10 mm | DWM-PE-100-22-10 | ||

| 12 mm | DWM-PE-100-22-12 | ||

| Flat Edge & Arris | Wheel Dia.Ф100mm | 4 mm | DWM-FA-100-22-4 |

| 5 mm | DWM-FA-100-22-5 | ||

| 6 mm | DWM-FA-100-22-6 | ||

| 8 mm | DWM-FA-100-22-8 | ||

| 10 mm | DWM-FA-100-22-10 | ||

| 12 mm | DWM-FA-100-22-12 | ||

| Remarks: Due to continuous improvement, wheel sizes and specifications may be varied without prior notice. | |||

| Polishing Wheels | |||

| Profiles | Specifications | Glass Thickness | Model Numbers |

| Applied for Almost Any Profile |

|

4 ~ 10 mm | PW-A-100-22-15 |

|

12 mm | PW-A-100-22-20 | |

| Remarks: Due to continuous improvement, wheel sizes and specifications may be varied without prior notice. | |||