Overview

Introduction

| Patent (Owned by Ianua SPA, Italy) | |

| Europe: | EP 0910553B1 |

| US: | 6470711B1 |

| China: | 97196155.7 |

| Register Trade Mark: | CONVAIR |

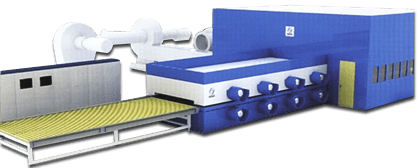

Ianua SPA, Italy develops a revolutionary patented heating and tempering system called CONVAIR® (Series Nr. HTM). Traditional heating system of glass tempering furnace is by irradiation. Irradiation process applies heat on top and bottom glass surfaces. Heat is then conducted into glass core gradually. Some heating is reflected from glass surface. There is heat loss. This phenomenon is particularly obvious on low-E glass. Great due amount of energy is lost in heating chamber. Heating efficiency of low-e glass is poor by heat irradiation due to low-e coating reflects irradiation. Air convection is one of the best known process to heat up low-e glass which is thermal transparent to heat irradiation. However, pure air convection glass tempering furnace would also heat up all metals inside furnace. Metals would eventually emit irradiation. This irradiation is out of control and thus, affects heating quality especially on clear and tint glass. Convection tempering furnace is not just pure convection. It is a combination of both hot air convection and irradiation. Instead of inducing cool air from workshop environment, hot air is re-circulated inside furnace. It is an enclosed force convection design. Air passes through heating resistors and heated. The heated air passes through nozzles and holes and eventually exerts on top and bottom glass surfaces. Air is then re-circulated and re-heated by heating resistor again. With combo convection and irradiation patented design, it could be easily optimize heating proportion between air convection and irradiation.