|

| The cutting tool is created

by advanced technology with good characteristic.

It has many advantages such as beautiful figure,

fine craftwork, good function, convenient operation

and close structure. The complete machine composes

of three parts: mainframe, cutting worktable and

operation table. The working state is steady and

cutting precision is very high. It also has great

protection when it is overload in abnormal condition.

This machine change the traditional cutting

way, it is very easy to cut all kinds of materials,

such as materials with great rigidity, steel,

rubber, glass, marble, composites and so on.

In cutting the temperature is no high than 80℃,

therefore there is no affection for molecule

structure and physical character of material.

|

| |

| System

Brief

1,

Industry control system

It provides complete Chinese

or English environment and help information.

It not only handles slots and any shapes, but

also that the cut can be initiated at any point

on the work piece.

2,pressurization part |

|

| It adopts fission plunger pump

that is made of stainless steel, the stability

is higher and the average time without malfunction

can compare with the oil-pressed type, but it

costs less on the equipment.

3,Working table

It adopts hanging design.

4,Digital control system

It has been totally transplanted from DOS to

WINDOS 98 operation flatform. Under the multithreading

and excellent EMS memory WINDOS 98, it achieves

to immediate automatic AUTOCAD plot output,

prompt cutting by control software and long-distance

control. The upgraded impulse, cooperating with

AUTOSAME, realizes a faster speed of the knife.

Technical

Specification

Our water jet cutting machine

has good quality of lancing and non breakage

material inner organization etc advantage for

widely use ceramic, glass and stainless. “Low

cost, high benefit” is great advantage of this

product, at present in glass industry it use

for lamp decoration, cleanliness, cookware,

electron and craft glass cutting, normal without

trouble cutting efficiency is 10000-12000 meter/month,

fit for 2-25 mm thickness, production cost is

only need 35 RMB/hour high pressure time, is

equal to cutting thickness 5-8mm need 24-36

meter/hour high pressure time. Favorable market

economic benefit, comparing with the other type

machine it has superiority.

In the control system, empolder and develop

product achieve big success. New servo system

has superiority characteristic. Traditional

step-process motor can not carry on automatically

impulse calculate insert when the control system

appears leap step; and it exists low frequency

resonance disadvantage, so it can not get excellent

plus minus speed steady transition in low speed,

bring on appearing leap knife phenomena, but

servo system can completely avoid this bad phenomena.

Due to servo system with high characteristic,

the price comparing with step-process system

is little expensive, is depends on customer

requested on system processing precision.

|

| |

| Technical

Data |

| Model |

WJ-3015-300 |

WJ-2415-300 |

WJ-2015-300 |

WJ-1613-300 |

WJ-1210-300 |

| Max

cutting range (mm) |

3000

x 1500 |

2400

x 1500 |

2000

x 1500 |

1600

x 1300 |

1200

x 1000 |

| The

max outer size of working table (mm) |

4000

x 2600 x 1860 |

3200

x 2400 x 1860 |

3000

x 2400 x 1860 |

2700

x 2700 x 1300 |

1900

x 1900 x 1300 |

| Travel

of knife rest (mm) |

0

- 80 |

| Driving

speed (Optional) |

Step-process

electric motor (mm/min) |

0

- 3000 |

| Servo

electric motor (mm/min) |

0

- 6000 |

| Adjusting

range of cutting pressure (Mpa) |

0

- 300 |

| Working

pressure (Mpa) |

180

?C 250 |

| Max

water flux (L/min) |

2 |

| Water

nozzle (stone) diameter (mm) |

Ø

0.25 ?C Ø0.3 |

| Inner

hole size of sand-mixed pipe (mm) |

Ø0.8

?C Ø1 |

| Mainframe electric motor |

Turning

speed(r/min) |

726 |

| Power (kw) |

18.5 |

| Air

compressor pressure (Mpa) |

0.6

?C 0.8 |

| Control

precision (mm) |

±0.25 |

| Cutting

precision (mm) |

±0.01 |

| Abrasive

material |

Garnet |

| Abrasive

granularity (eye) |

60

?C 100 |

| Micro-computer |

ipc686 |

| Program

software |

Water

jet digital control system (CAM) |

| Mainframe

max outer size (mm) |

2000

x 900 x 900 |

| Operation

table max outer size (mm) |

650

x 550 x 1760 |

| Weight

(kg) |

3400 |

3000 |

2900 |

2300 |

1900 |

|

|

|

|

|

|

|

|

|

| |

| Consumable

Data |

| Consumables |

Nozzle |

Pump encapsulation |

Valve release

needle |

Single

direction

valve |

Injection

pole with cover |

| Life time (hr) |

100-150 |

500 |

|

| |

| Cut product

samples |

|

| |

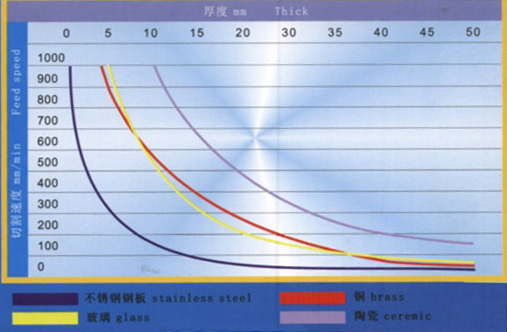

| Different

material cutting speed sketch map |

|

| |

|

|