Features

Structure

General

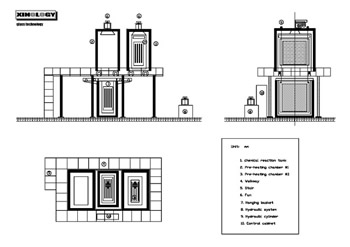

FR series fire resistant glass production equipment is a double deck design. The structure is simple with only little tricks. It consists of,

- Pre-Heating Ovens (Two)

- Horizontal Moving System (One)

- Glass Racks (Two)

- Lifting Systems (Two)

- Chemical Ion Exchange Bath Tank (One)

- Upper Floor Platform (One)

- One Control System (One)

All parts and components are carefully selected for heavy duty purposes while they are standard available everywhere. All parts in contact with chemicals are corrosive proof.

Pre-Heating Ovens

There are two pre-heating ovens locating on upper floor of the system. One is on left and another is on right. It is a compact design like a sturdy box. There is a hot air blower on top of each glass pre-heating ovens. The heat resistant hot air fan is powerful enough to create an evenly heat distributed hot air convection environment inside the pre-heating oven. Glass to be chemically treated is pre-heated to certain temperature inside the oven before dipping inside the chemical tank.

Each of the pre-heating chambers is made of steel plate with heat insulation materials which is used to prevent heat loss during heating. This reduces heat power consumption. The oven floor acts as a door access. It is opened and closed controlled automatically. The two ovens has wheels which is used to freely move horizontally close or away to each other along track rails which are mounted on upper floor.

Horizontal Moving System

This moving mechanism located on upper floor. It comes with a track rails where the two pre-heating ovens lie on. A strong motor with gear reducer and chain system is used to move the two ovens close to or away from each other along track rail. When glass is pre-heated to set temperature ready for chemically strengthening, the motor would start and drive the pre-heating oven towards another pre-heating oven until it is right above ion-exchange tank.

Glass Racks

There are two stainless steel glass racks. One is put on left hand side right beneath left pre-heating oven. Another is put on right hand side right beneath right pre-heating oven. Each of the rack is in compact design. The rack is sturdy and is strong enough to hold large quantity of glass.

Both glass racks could be vertically lifted up to above pre-heating ovens by accessing through oven bottom doors.

Buyer shall build two baskets. Each basket is put on one glass rack. Glass is put inside the basket. If necessary, proper jigs and fixtures are design and built by buyer to hold glass in position inside the baskets. This is particular important if glass is tiny.

Lifting Mechanisms

There are two lifting systems. One is on left hand side and another is on right hand side of the system. The lifting system is used to raise the glass rack into pre-heating oven.

Chemical Ion Exchange Bath Tank

The tank is located on ground floor. Carefully selected stainless steel is used to construct this tank. The stainless steel is welded by first class certified workmanship with special welding rod. It is well insulated by special thick heat insulated materials preventing heat loss to save energy consumption. This box type compact design tank has a top opening. It is open and closed controlled automatically.

Glass rack is lowered down onto the chemical tank through the top access. The tank is filled with potassium salt and special catalyst. Glass carried by glass basket placing on glass rack is eventually put inside this chemical bath for ion exchanging. There is a heating system to maintain the chemical reaction occurred under requested temperature.

A sophisticated stirring system is equipped to mix the melted potassium and catalyst constantly. This helps salt concentration evenly distributed across the fluid bath.

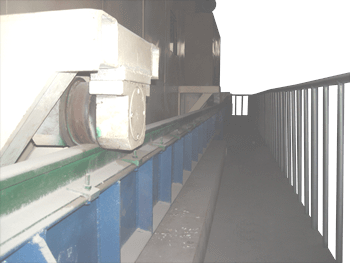

Upper Floor Platform

A steel structure upper floor platform comes with the equipment. The structure is strong enough to withstand the two pre-heating ovens. Protective fences are provided for safety purpose. There is also a staircase accessing to the platform. Operator could easily access for better observation, maintenance and filling of salt and additives as well.

Control System

It is a standalone control console. All parameters including salt stirring, pre-heating temperature, heating time, ion exchanging temperature and chemical reaction time are set in this system. It also controls glass racking lifting system, pre-heating oven horizontal moving system and door opening as well. All controls of the system are achieved from this console.