Features

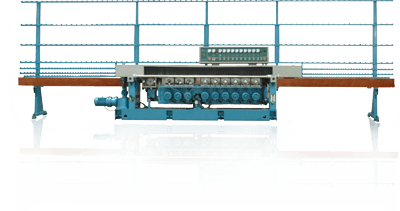

G-VB-371A

Highlights

- 11 spindles G-VB-371A vertical glass straight bevelling machine

- HMI touch panel operator interface

- PLC controlled glass thickness, bevel width and bevel angle regulated from HMI

- Pneumatic cylinders for felt polishing wheels controlled by PLC

- Up to 40mm bevel width

- 100 x 100mm can be beveled without moving beam up and down

- Glass travel speed regulated by frequency converter

- Direct drive spindles ensure enough pressure acting on glass bevel surface

- Consistent travel speed of timing belts at inlet and outlet conveyors

- Two individual water recirculation tanks for water and polishing powder running separately

- Non-scratch glass leaning rack's rollers

Specifications

| Model | G-VB-371A |

| Bevel Profile | Bevel & bottom pencil edge |

| Nr. Of Spindles | 11 |

| PLC | Control glass thickness, bevel height, bevel angle & polishing spindles pneumatic cylinders |

| Glass Thickness | 3 ~ 25 mm |

| Bevel Angle | 3º ~ 30º |

| Bevel Width | 0 ~ 35 mm |

| Glass Speed | 0.4 ~ 4 m/min. |

| Min. Glass Size | 100 x 100 mm |

| Max. Glass Loading | 300 kg |

| Main Convey | Chain |

| Spindles Motors | All custom made AC motors by ABB |

| Bevel Angle Adjustment | Input in HMI regulating AC motor with encoder controlled by PLC, parameters displayed on HMI |

| Bevel Width Adjustment | Input in HMI regulating AC motor with encoder controlled by PLC, parameters displayed on HMI |

| Glass Thickness Adjustment | Input in HMI regulating AC motor with encoder controlled by PLC, parameters displayed on HMI |

| Glass Speed Adjustment | Turning knob on panel with frequency convertor |

| Inlet/outlet Convey | Timing Belts |

| Water Tanks | Two (one for water, another for polishing) |

| Water Pumps Motors | AC Motors (0.25 kW for water / 0.12 kW for polishing powder) |

| Power | 25.7 kW |

| Voltage | AC 380V / 3 phase / 50Hz (others on request) |

| Weight | 4500 kg |

| Outer Dimensions (L x W x H) | 7500 x 2000 x 2600 mm |

Wheels Configuration

#11 |

#10 |

#9 |

#8 |

#7 |

#6 |

#5 |

#4 |

#3 |

#2 |

#1 |

Positions Schematics |

|

| Cup | Cup | Cup | Cup | Cup | Cup | Cup | Peripheral | Cup | Cup | Cup | Forms | |

| Felt | Felt | Felt | Resin Diamond | Resin Diamond | Resin Diamond | Resin Diamond | Metal Diamond | Metal Diamond | Metal Diamond | Metal Diamond | Materials | |

| Bright Bevel Polishing | Bright Bevel Polishing | Bright Bevel Polishing | Fine Bevel Grinding | Fine Bevel Grinding | Fine Bevel Grinding | Fine Bevel Grinding | Bottom Pencil Edging | Coarse Bevel Grinding | Coarse Bevel Grinding | Coarse Bevel Grinding | Applications | |

| Φ150 | Φ150 | Φ150 | Φ150 | Φ150 | Φ150 | Φ150 | Φ175 | Φ150 | Φ150 | Φ150 | OD | Sizes (mm) |

| Φ22 | Φ22 | Φ22 | Φ22 | Φ22 | Φ22 | Φ22 | Φ22 | Φ22 | Φ22 | Φ22 | ID | |

| NA | NA | NA | #600 | #480 | #360 | #240 | #180 | #320 | #230 | #80 | Grit | |

| AC 1.5 | AC 1.5 | AC 1.5 | AC 2.2 | AC 2.2 | AC 2.2 | AC 2.2 | AC 1.75 | AC 2.2 | AC 2.2 | AC 2.2 | Motors Power (kW) | |

| Pneu matic |

Pneu matic |

Pneu matic |

Mech anical |

Mech anical |

Mech anical |

Mech anical |

Mech anical |

Mech anical |

Mech anical |

Mech anical |

Spindles Feeding | |